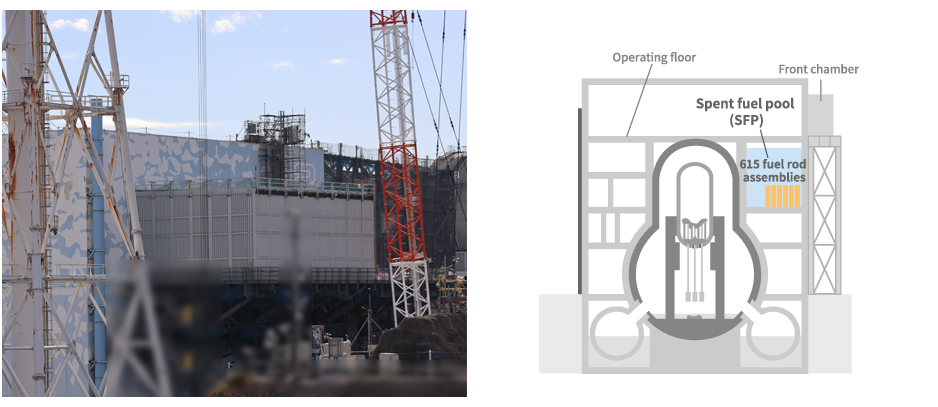

Fuel Removal from Unit 2 Spent Fuel Pool

The spent fuel pool in the upper part of the reactor building stores fuel rod assemblies that were used to generate electric power. Hydrogen explosions occurred in Units 1, 3, and 4, whereas Unit 2 was spared such an explosion because hydrogen escaped through the partially collapsed walls of the reactor building.

We are working in preparation for the commencement of fuel removal in the first quarter of FY2026.

Unit 2 Status

Progress Status

Step 1: Survey of internal state

Operating floor surveys were conducted on the way to fuel rod removal.

Step 2: Installation of "fuel removal platform/front chamber/opening/runway girder*" on the south side of reactor building

(*) Foundation for rails that will enable the fuel handling machine to move between the reactor building and the front chamber.

Completed in March 2025.

Step 3: Installation of a fuel handling facility

Fuel handling equipment will be brought to the port of the Fukushima Daiichi Nuclear Power Station by sea, transported by supercarriers from the port to the vicinity of the fuel removal work platform, and then lifted onto the fuel removal work platform by cranes.

Completion of Transportation of the Fuel Handling Equipment into the Site (link to reference material) (409KB)

Completion of Transportation of Fuel Handling Equipment to the Fuel Removal Work Platform (link to reference material) (421MB)

Click here for the status of packing removal for fuel handling equipment (Period: May 28, 2025 to June 5, 2025)

Click here for the test operation status of fuel handling equipment to be used to remove Unit 2 fuel (Period: December 23, 2025 to January 9, 2026)

Step 4: Removal of spent fuel

-

Completed

-

Surveys inside Reactor Building

In preparation for removal of fuel from the spent fuel pool of Unit 2, a room called a front chamber was built on the west side of the Unit 2 reactor building. Then in June 2018, an outer wall opening was completed on the west side of the building. Survey work inside the operating floor has now been conducted in advance of studies on measure to suppress scattering of radioactive materials when the upper part of the reactor building is dismantled.

Construction of a Fuel Handling Facility (Access Gantry+Front Chamber) on the South Side of the Reactor Building

The first priority in devising the fuel removal method is ensuring the safety of the surrounding area. After studies were conducted based on various risk scenarios, it was decided to revise the plans calling for dismantling of the upper part of the reactor building, given the downward trend in air dose rates on the operating floor. Following the revision, a fuel handling facility (access gantry+front chamber) is being constructed for transporting fuel rod assemblies out of the building on the south side. By connecting the front chamber and the building, a fuel removal system will be carried in and set up on the operating floor, and fuel will be removed by remote operation. Since this method does not involve dismantling of the upper part of the building, work can be performed in a state in which dust, including radioactive materials, is controlled.