IGCC: Eco-Friendly and Highly Efficient Coal Thermal Power

Our Efforts

Ever since the former Clean Coal Power R&D Co., Ltd. started producing demonstration equipment, we have been developing IGCC (integrated coal gasification combined cycle) technologies, which utilize coal in a highly efficient manner, boast excellent environmental performance and profitability, and offer an extremely high level of energy security. With the aim of reducing CO2 emissions, we use all our available technologies and knowledge necessary to ensure a highly effective use of coal. We also provide technical assistance in the construction and operation of the Fukushima IGCC project.

What Is IGCC (Integrated Coal Gasification Combined Cycle)?

The abbreviation "IGCC" stands for "integrated coal gasification combined cycle."

Conventional coal-fired thermal power stations burn coal and use the heat to produce steam. The steam powers the steam turbines, which then generate electricity. The IGCC technology, on the other hand, gasifies coal and uses a combined cycle (a combination of gas and steam turbines) to generate electricity. Power stations using this method generate electricity more efficiently than conventional coal-fired thermal power stations of a similar size (with a thermal efficiency at the sending end (LHV) of approximately 48%) and reduce CO2 emissions by approximately 15%. This technology also allows us to use coal with a low ash melting point, which is not suitable for conventional coal-fired thermal power stations.

Characteristics of IGCC (Integrated Coal Gasification Combined Cycle)

| High power generation efficiency |

|

|---|---|

| Broader range of suitable coal types |

|

| Eco-friendly characteristics |

|

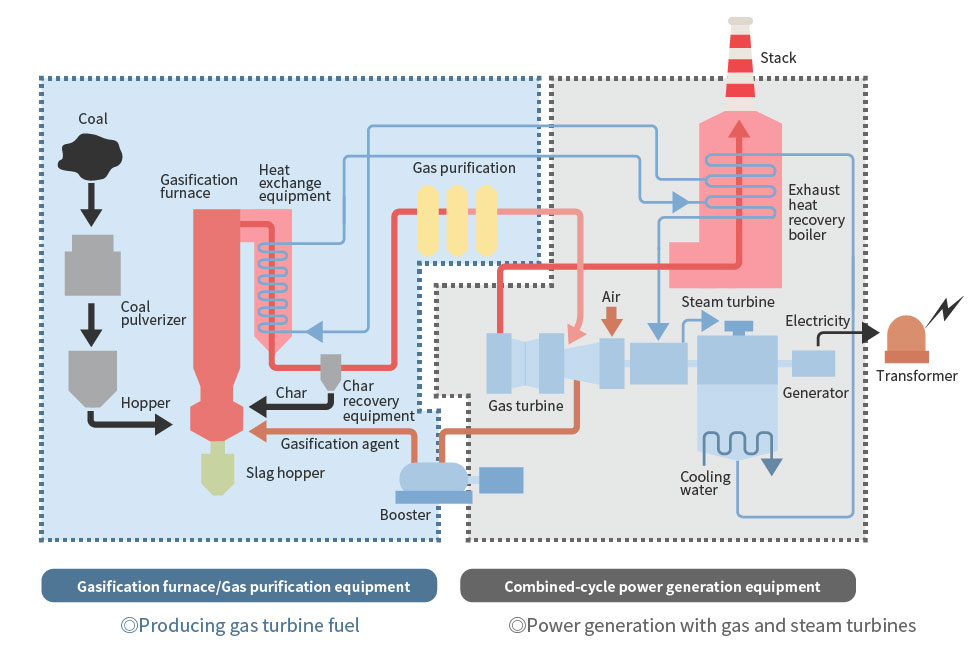

Power Generation Structure

- Coal is gasified inside a gasification furnace to generate fuel gas.

- The fuel gas is then fed to a gas turbine and burned there in order to power the gas turbine.

- The hot exhaust gas generated in the gas turbine is then fed to an exhaust heat recovery boiler, where it generates the steam necessary to power the steam turbine.

- *Char:

This is unreacted solid substance generated inside a gasification furnace after all the volatile matter and water have been removed from coal. It mostly consists of ash and fixed carbon.

- *Slag:

This glass-like solid substance is generated when the ash contained in coal melts at a high temperature inside a gasification furnace, falls into the water at the bottom of the gasification furnace, where it is then quenched. Slag is emitted in granular form.

- *Hopper:

Storage tank