System for Continuous Pipe Wall Thickness Measurement Using Flexdry UTM

Overview

We developed an online monitoring device capable of performing online monitoring of wall thinning that occurs over time in the piping of thermal and nuclear power stations. We developed thin flexible probes not requiring coupling material and multi-channel monitoring equipment. This equipment can reduce the inspection period. We are performing demonstration testing for use in nuclear power stations.

Background

The walls of piping in thermal and nuclear power stations become thin over time, making it necessary to periodically perform wall-thinning management. As the number of locations requiring inspection has reached several hundred annually, measurements are one cause of increased labor-hours during periodic inspection due to the stopping of plant operations to perform such measurements.

Features

- The probes are thin, small, and flexible, with two oscillators, making them perfect for detecting corroded piping.

- The newly developed dry-coupling layer eliminates the need for a coupling medium. It includes a function to detect and automatically correct changes in the thickness of the dry coupling layer.

Probe (External View)

Probe (External View): Flexibility

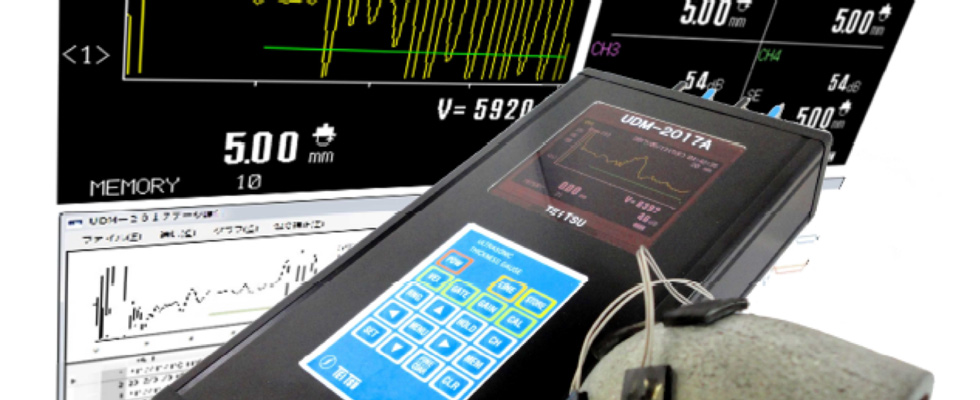

Continuous Pipe Wall Thickness Measurement Device: Wireless-Compatible Multi-Channel Model

Demonstration Testing on Actual Equipment at Power Station

Continuous Measurement of Pipe Wall Thickness