Disaster Analysis Method – SAFER –

Background

We have focused on the actual conditions that induce human errors from situations where "the surrounding environment does not match human characteristics" and are analyzing the cause of errors from a variety of perspectives in order to consider measures to reduce errors by improving the work environment. TEPCO has developed the "SAFER" analysis method for accidents and similar incidents, and are applying this method throughout the company.

Main Results

Analysis Using SAFER

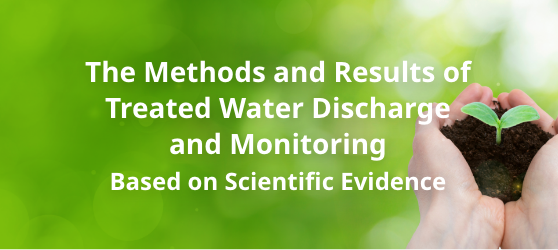

The SAFER (Systematic Approach For Error Reduction) analysis method uses an m-SHEL model to analyze the cause of the accident or similar incident from a variety of perspectives in order to devise countermeasures that decrease the occurrence risk of such accidents. It has been applied to improve causes in the environment surrounding humans to better match human characteristics in order to prevent errors by creating a "Human-centric environment".

Conceptual Model Showing the Human Factor Approach

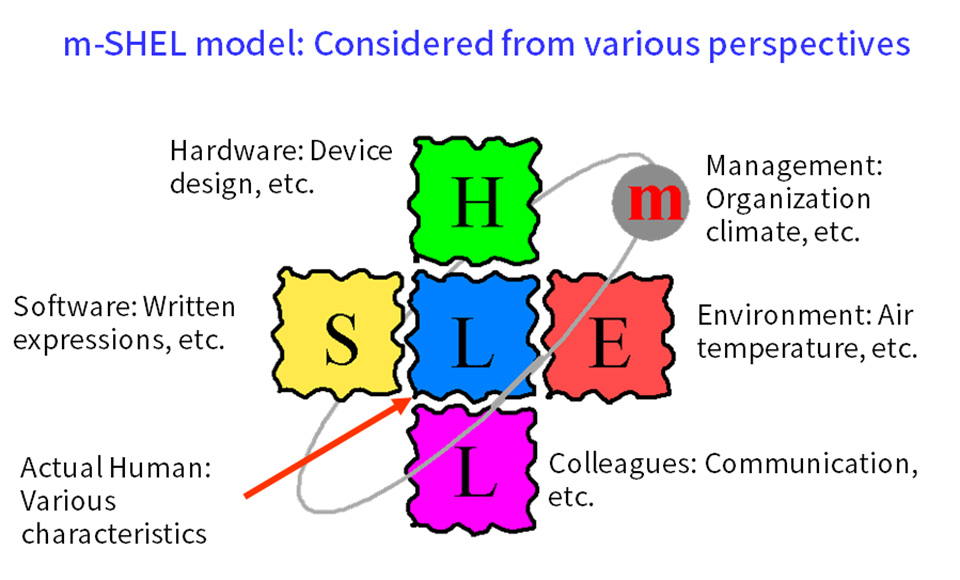

SAFER Analysis Procedures

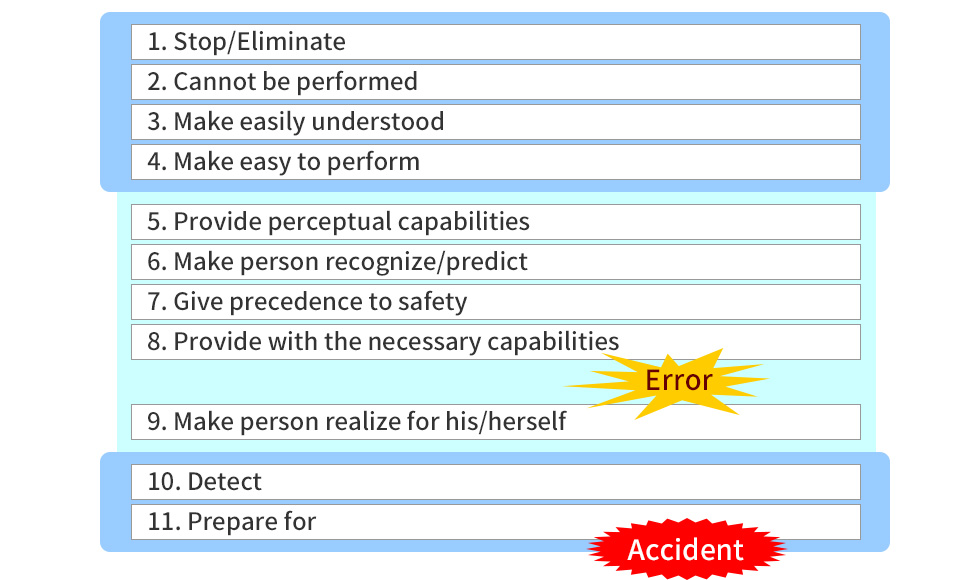

Guidelines for Conceiving Error Countermeasures

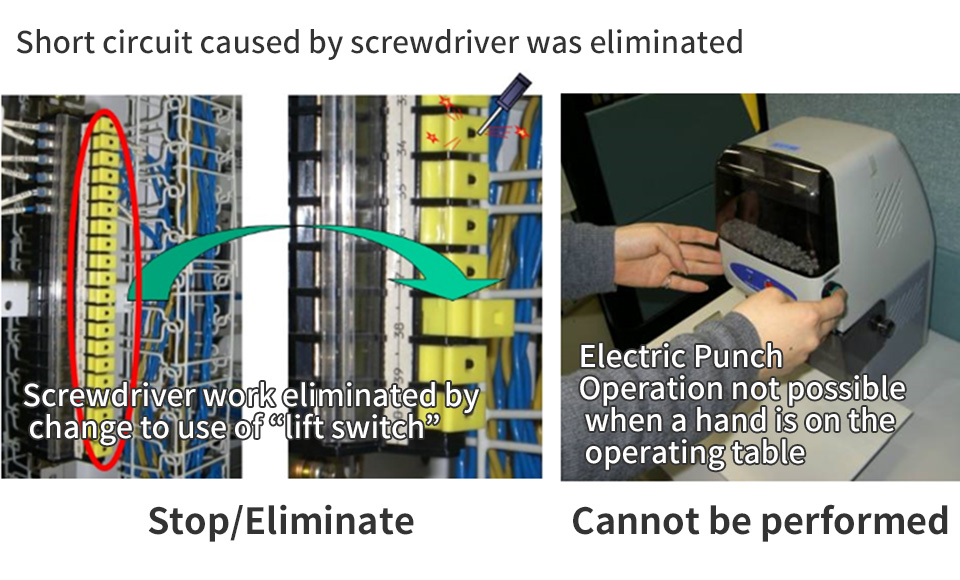

The Guidelines for Conceiving Error Countermeasures has been developed based on SAFER and is used to create countermeasures that rely on human awareness and similar factors as little as possible. We reduce the risk of accident based on concepts such as "Reduce the possibility of risk due to automation and process changes ('Stop/Eliminate')", "Physical protection by covering, locking, and similar measures ('Cannot be performed')", and "Reduce the burden of judgment by color-coding and marking ('Make easily understood')".

Guidelines for Conceiving Error Countermeasures

Examples of Effective Countermeasures

Applications and Examples of Results

SAFER is being applied to the analysis of accident causes at TEPCO's wide variety of facilities and workplaces, as well as for establishing corresponding countermeasures. We are also carrying out company-wide training about the method. Its application is not limited to maintenance management of our facilities and equipment, but also covers a wide variety of work including production plants and desktop management.