2.5 Countermeasures against Other Risks

1) Countermeasures against groundwater contamination

For the highly contaminated water that had leaked into the basement of the building (accumulated water) is processed and reused for water injection into the reactor by the "circulating water cooling system", we were able to reduce the total amount of accumulated water by increasing the capacity of the water processing facilities.

We are maintaining the accumulated water in the basement at a certain level because if it leaks up to the ground, it will pose a contamination risk. On the other hand, if the decrease of this accumulated water level is too great, it will accelerate the rate of accumulation due to the inflow of ground water resulting in more water processing work.

Hence, the key is to transfer just the right amount of accumulated water from the basement to the processing facilities in order to control the downward inflow amounts of ground water.

Figure 10. Situation of water level at the basement of Unit 2, 3 turbine building

In January and February 2012, it is presumed that the cause of about 30 incidents of water leakage was due to pipe pressure fluctuation caused by water freezing at various points. Since December 2011, we implemented anti-freezing countermeasures such as installing heat insulation materials on certain piping that carries highly contaminated water and is used to inject water into the reactor. Although we did our best to move forward as fast as we could with the heat insulation anti-freezing countermeasures, our efforts were unfortunately not fast enough to cover the piping that carries the non-radioactive water such as filtered water. It was certain areas of these pipes that froze up resulting in leakages that we were unable to prevent. In addition even the areas that were treated still succumbed to freezing.

After that, in an attempt to cut down on the leakage risk due to freezing, we implemented additional countermeasures such as 'housing treatment' (preventing the machine and piping from being exposed to rain and snow) as well as installing additional heat insulating materials.

Furthermore, as of February 21, 2012, approximately 120,000 tons of processed water that was highly contaminated was stored on the site premises. There are still some radioactive materials contained in this decontaminated water. Hence, storing it safely is an important issue. First, reliability is enhanced by monitoring the condition of the pipes and tanks and replacing them if necessary in order to reduce leakage risks. Next, in the former half of FY2012, we will proceed with the installation of 'multi-nuclide removal facilities' in order to reduce the amount of radioactive materials contained in the decontaminated water to a level below the legal concentration limit where there is no impact to the environment should a leakage occur.

Situation of water level, transfer and treatment of the accumulated water

2) Worker safety

Although TEPCO employees and partner company workers have not suffered from radiation exposure to date, up until February, 2012, 6 TEPCO employees were exposed to an amount exceeding the 250 mSv legal dose limit set for emergency work* (no partner company workers exceeded 250mSv).

* For more details, please refer " Emergency Exposure Dose Limits"

Their maximum exposure levels were 678.80 mSv (Minimum of 310.97 mSv). The primary factor pinpointed was iodine 131, a radioactive material that employees inhaled through their full-face mask openings while engaged in immediate post accident recovery work.

Furthermore, on March 24 2011, 3 partner company workers were exposed to a maximum radiation dose of 238.42 mSv due to getting their legs drenched in highly contaminated water while working at the basement floor of the Unit 3 Turbine building (Minimum of 175.62 mSv).

As a result of this exposure to highly contaminated water, they were expected to suffer from ray burns. However, upon examining them, the National Institution of Radiological Sciences did not detect any abnormalities. Currently, these 9 members have been removed from onsite work.

Although for a short period of time following the accident, we had run short of alarm pocket dosimeters (APD) (external exposure measuring instruments) and whole body counters (WBC) (internal exposure measuring instruments), we now have a sufficient number of these devices on hand. Furthermore, workers whose exposure levels exceeded 100 mSv or are engaged in emergency work for more than one month undergo monthly health checks.

Furthermore, workers whose exposure levels exceeded 100 mSv or engaged in emergency work for more than one month undergo monthly health checks.

In addition, we have established an onsite emergency medical room, have a resident doctor on standby 24/7, instituted countermeasures against heatstroke such as setting up resting rooms and distributing cooling vests and all of the over 5,000 workers have also received free influenza vaccinations in winter. We are making oututmost efforts to secure worker health.

s

Table2. Distribution of the total of external and internal exposure doses

Status of exposure dose evaluation

(Explanation) Radiation Measuring Method

[Video] Vol.3:Radiation Monitoring at the site -No.1 measuring method25:08

Opening of Whole-Body Counter (WBC) Building at J-Village July 11, 2011![]()

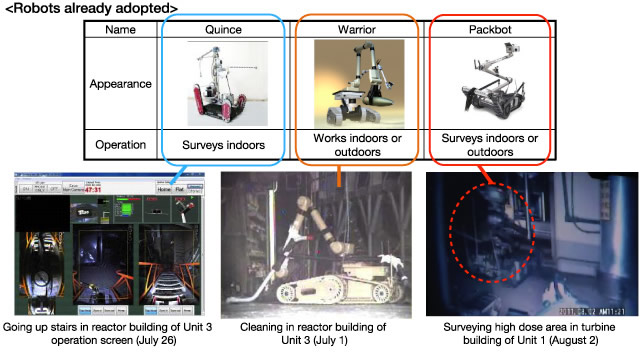

At both inside and outside high radiation dose areas, we have utilized robots since April 2011 to measure the radiation dose inside the building and remove the high radiation debris at the outside. These works were done by wireless remote-controlled robots.

Unmanned helicopters were also used. We procured the helicopters and robots from both domestic and overseas sources.

Figure 11. Examples of robots introduced to the site

[Video] Robot:Quince (video on June 6,2011) 00:42

[Video] The videos were taken by the Packbot inside the nuclear reactor building of Fukushima Daiichi Nuclear Power Station.

1st Floor, Nuclear Reactor Building, Unit 1 (video on April 17,2011)00:28 14 in total

1st Floor, Nuclear Reactor Building, Unit 2 (video on April 18,2011)00:20 8 in total

1st Floor, Nuclear Reactor Building, Unit 3(1) (video on April 17,2011)00:32