Participation in the TetraSpar offshore floating wind turbine foundation demonstrator project

Project Overview

TEPCO RP has been participating in the TetraSpar offshore floating wind turbine foundation demonstrator project jointly run by RWE Renewables (hereinafter referred to as, “RWE”), Shell New Energies (hereinafter referred to as, “Shell”) and Stiesdal Offshore Technologies A/S (hereinafter referred to as, “SOT”) since February 2021.

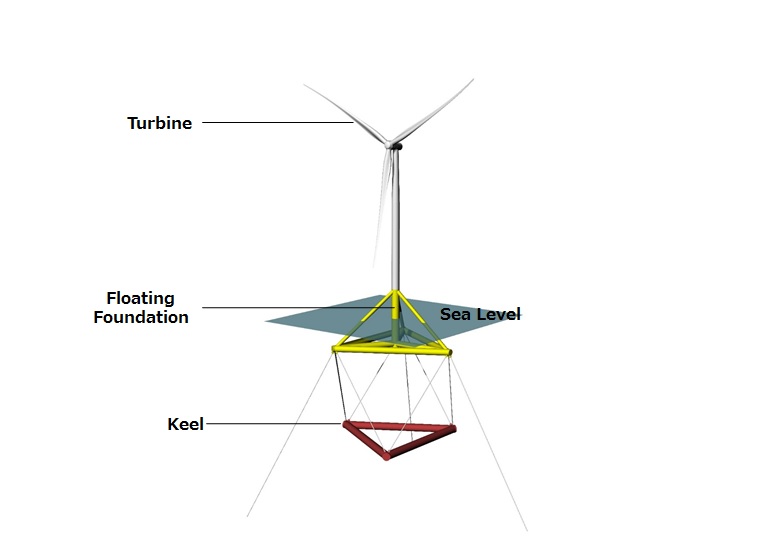

TetraSpar Demonstrator ApS (hereinafter referred to as, “TSD”), which was established in Denmark to carry out this demonstrator project, assembled the floating module of the demonstrator on land at Port Grenaa, Denmark in May 2021. The floating module was then submerged and a land-based crane was used to erect the wind turbine inside the port. After this, the wind turbine and floating foundation were towed to the Marine Energy Test Centre (MET Centre) near Stravenger, Norway, and anchored in water 200m deep using three mooring lines attached to the seafloor. The demonstrator was then connected to Norway’s power grid.

In November 2021, the demonstrator was brought online (one turbine with an output of 3,600kW), and will be operated for a trial period of three to five years in order to gather data, and analyze performance and attributes, with the aim of quickly establishing the necessary technologies for operation.

The TetraSpar offers important competitive advantages over existing floating wind turbine concepts due to its potential to enable leaner manufacturing, assembly, and installation processes at lower costs.

Through this project, TSD and the participating four companies will continue to work to bring this concept to fruition and strive to make further improvements.

Demonstrator Project Overview

| Name | TetraSpar Demonstrator Project |

|---|---|

| Location | Marine Energy Test Centre (Norway) |

| Output (Number of turbines) | 3,600kW (1 wind turbine) |

| Company Name | TetraSpar Demonstrator ApS (Denmark) |

| Business | Perform experiments and demonstrate the TetraSpar offshore floating wind turbine demonstrator |

*Local company established to carry out the demonstrator project

Participating companies

| Participating companies | |||

|---|---|---|---|

| Stiesdal Offshore Technologies | Shell | RWE | TEPCO RP |

| Established by former CTO of Siemens Wind Power, Henrik Stiesdal. Invented the TestraSpar technology | Global oil and gas company focusing on growth areas of the energy industry | Second-largest power company in Germany, and second-largest offshore wind power company in the world | Leveraging its success with experimental wind turbines off the coast of Choshi to develop offshore wind power in Japan and overseas |

Reasons for Participating in the Demonstrator Project

- As TEPCO RP promotes the use of offshore wind power both within Japan and overseas, it is important that we own floating offshore wind power turbine technology that is expected to grow in the future.

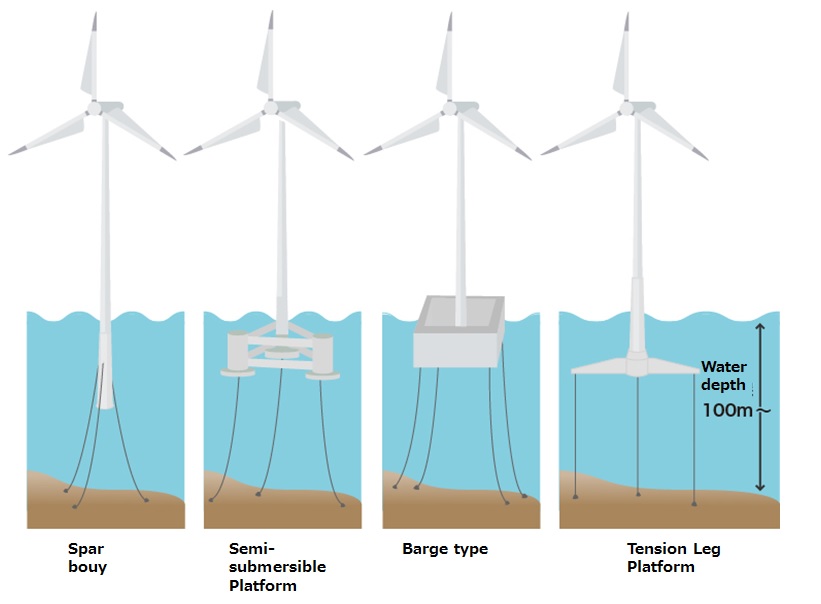

- There are many types of floating offshore wind power foundations, such as spar buoy (spar), and semi-submersible (semi-sub), etc., but there is no de facto technology, and various technologies are being developed.

- After determining that the TetraSpar floating foundation technology is a promising type of offshore wind turbine foundation, TEPCO RP has sought to quickly acquire technical expertise and know-how by participating in this demonstrator project.

- The TetraSpar has been designed and developed with commercialization in mind, and enables the use of existing supply chains. Therefore, the technology makes it easy to build regional supply chains for the manufacturing of parts in local factories, for example.

- The floating foundation is small in mass and requires no welding or special port facilities for assembly or turbine installation therefore enabling low-cost manufacturing, assembly, and commissioning.

- As with spar foundations, only a small portion of the TetraSpar foundation is in contact with the ocean surface. This makes it less affected by waves and tidal currents, and this concept can be utilized in Japan’s natural conditions.

Features of TetraSpar

| Method | Features |

|---|---|

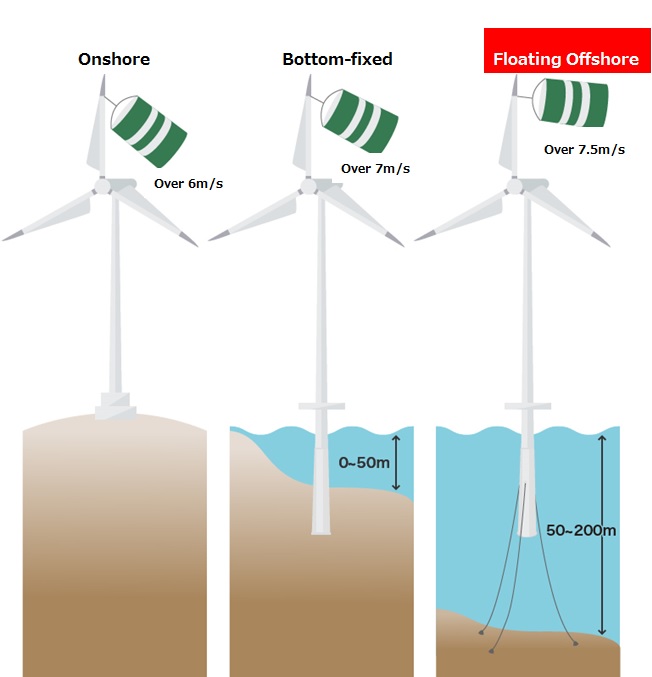

| Onshore | Installed on land |

| Bottom-fixed | Fix the foundation of a wind turbine to the seabed ground at a depth of about 0 to 50 m. |

| Floating Offshore | Installed offshore at a depth of about 50 to 200 m. Supports the wind turbine with a floating body, and keeps the position with a mooring line. |

| Method | Features |

|---|---|

| Spar bouy | Cylindrical floating body type. water surface penetration is small. Not easily affected by waves. |

| Semi-submersible Platform | A floating body type that combines multiple floating bodies and submerges them in half. Water surface penetration is relatively small. Not easily affected by waves. |

| Barge type | Box-shaped floating body type. Easily affected by swell. |

| Tension Leg Platform | A form in which the seabed and the floating body are connected by an elongated elastic member and held by the tension. Difficult to construct. |

TEPCO RP aims to realize a large-scale wind-farm in Japan for floating offshore wind turbines after the late 2020s.