Construction, operations and maintenance support

Since infrastructure is shared over long periods of time it is important to build facilities from the standpoint of how much maintenance costs can be reduced and to what degree the equipment can be made efficient. In addition, it is often the case that work is suspended for inspections and maintenance, the plants are shut down due to an increase in water caused by typhoons and others, and power cannot be generated due to unforeseen troubles, such as part malfunctions. By leveraging the technical skill and knowledge that we have cultivated over many years through our hydroelectric power business, TEPCO will provide support for everything from the construction to the operation and maintenance of power stations, and also aid with optimizing equipment and making power generation management more efficient, which are often problem areas.

Please call the following number for more information.

Hydro Power Planning Group, Hydro Power Department, TEPCO Renewable Power, Inc.

+81-(0)3-6373-1111

Hours of operation: 9 AM to 5 PM (excluding weekends, holidays, and New Year’s holiday)

- Building

- Protecting

- Using

“Building” hydroelectric power plants

Supporting optimal facility design from the viewpoint of users

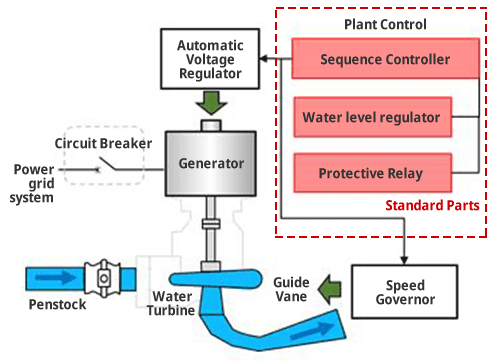

All kinds of different control sequences depending on the power plant

Difficult for the user to make repairs or change settings

Standardization of power plant control functions

Design of control equipment that can be built from standard parts

Standard sequence applying knowledge about operation, maintenance, trouble, etc.

Applicable to diverse types of power plants

“Protecting” hydroelectric power plants

Supporting risk response with diagnostic and assessment technologies

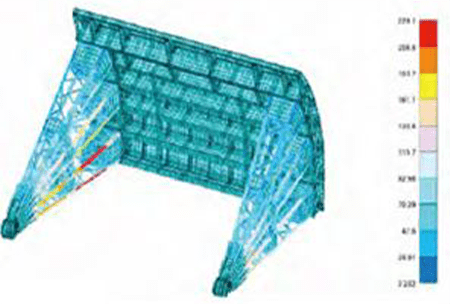

Supporting assessment of equipment performance in major earthquake, and reinforcement planning

Supporting equipment safety, such as graphing and assessing measurement data, and alarm setting

Gate aseismic performance investigation

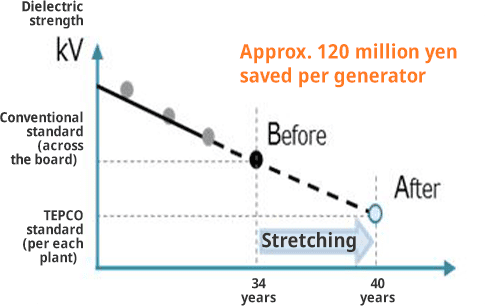

Repair costs can be reduced by equipment diagnosis technology

Generally, generator replacement timing is uniform (CRIEPI finding)

Replacement period can be extended by conducting lightning surge analysis of individual plants (setting of individual replacement standards)

Note: Cost savings amount is typical for 300MW class power station

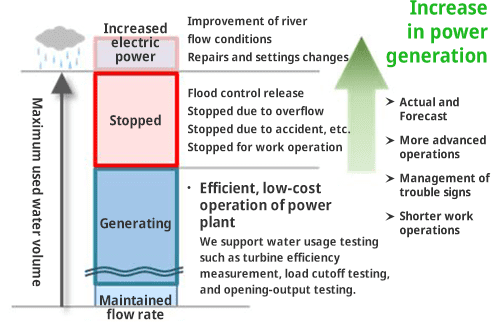

“Using” hydroelectric power plants

Supporting efficient operation and increased power generation

Diagnosis of utilization rate based on river flow conditions

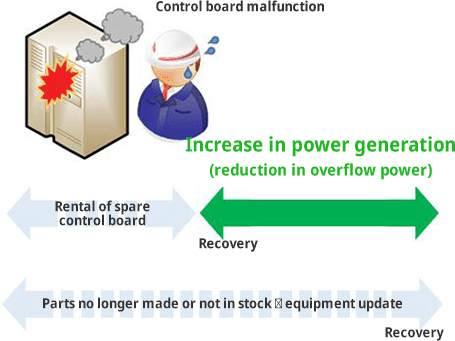

Rent parts from our stocked supplies until recovery (avoid long-term stoppage)

Difficulty obtaining repair parts for old control equipment