In view of engineering technology, we have many and various experience regarding dam, tunnel, underground powerhouse, penstock, headrace, tailrace and so on taking into consideration both of minimum cost and environmentally friendly development.

Our services are not only design and construction supervision but also operation and maintenance with the aim of achieving sustainable development and water efficiency use.

TEPCO also offers suitable engineering services for IPP hydropower projects for planning, design, construction supervision, operation and maintenance.

Turbine oil is used as bearing lubrication oil for hydraulic turbine generators. It is analyzed oil viscosity, water content, oxidation degree, etc. including temperature watching, because of prevention of bearing metal abrasion.

In general, oxide compounds and worn particles increase over time and may invite bad conditions such as temperature increase of bearing metal, poor lubrication, etc.

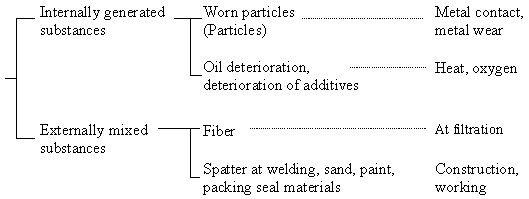

The contaminants are classified in Table 1. In order to find a sign of bad

condition, the properties of worn particles in the oil are checked to diagnose

lubrication in operation.

Therefore the diagnostic equipment is developed by cooperative research

(Fig. 2).

Fig. 2 Diagnostic equipment for lubricating oil

© Tokyo Electric Power Company Holdings, Inc.