Construction

Operation & Maintenance

Substation

TEPCO have 1577 substations in 2005. We have built a variety of substations

depending on their purpose, supplying voltage, installing cost, and its supplying

area. 500kV large-scale underground type substation has been built for stable

and efficient supply for Tokyo metropolitan area.

Even though we operate a variety of substations and machineries, We have

achieved very low annual average electricity interrupting time. For stable

supply, we have introduced many up-to-date techniques. And we have organized

quality management system for substation design and construction (e.g. Guidelines

for installation of SF6 Gas Insulated Switchgears.). And we have developed

effective diagnostic/maintenance techniques for every machinery (e.g. dissolved

gas analysis and circuit breaker operation monitoring are employed).

We can offer the best solutions for substation construction/operation from

our technical experience.

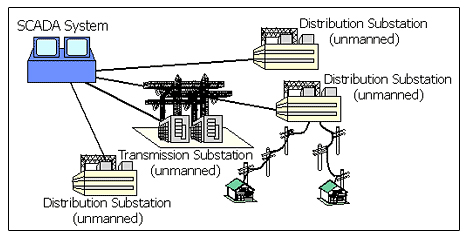

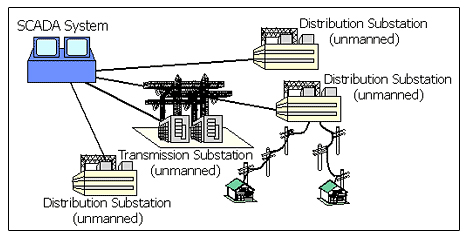

Substation Control Automation (SCADA)

SCADA System

RTU (Remote Terminal Unit) installed in distribution & transmission substations

and SCADA system can make substations unmanned and remote monitoring and controlling

substations possible.

TEPCO's SCADA Technology

- High Reliability

Doubling main parts and TEPCO's much experience about SCADA system design

can realize high reliability & availability.

- Monitoring Substations

Automatic monitoring and displaying of substation condition can be conducted

based on the information from RTUs.

- Operation of Substation equipment

Manual operation by operators and automatic operation

by SCADA system are possible.

- Automatic Message

SCADA system can edit messages about fault information, etc. and messages

are reported to related offices automatically.

- Substation Operation Supporting Function

Various information needed for substation operation (operation

record, load status record, etc.) can be generated automatically.