Construction

Operation & Maintenance

Overhead Transmission Line

Over the years, TEPCO has coped successfully with the various challenging

issues facing overhead transmission lines. The issues include how to build

mechanically robust transmission facilities which withstand harsh inclement

conditions, such as severe thunderstorms, typhoons, heavy icy rain and snow,

and salty rains, etc. We also succeeded in minimizing the effects of corona

discharge emitted from wires as well as of thunderbolts, while we need to

ensure that we find the exact location of a flashover once a tower is hit

by a lightning. We are sometimes required to put transmission towers in a

very limited space or reconstruct in urban congested areas, or put towers

in a mountainous area, both of which we finished successfully by redesigning

the towers so as to fit the environment.

Therefore, if you face similar issues, TEPCO's consulting services are exactly

what you need. We would help you find the best solution for design, construction,

maintenance, diagnosis with aging, voltage upgrading, fault locating, accurate

distance measurement to ambient structures and other miscellaneous issues.

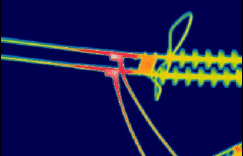

Overheating of Overhead Transmission Wire Splice/Joint

The Cause of overheating

- Bad construction (position mistake of steel sleeve etc.)

- Degradation of contact

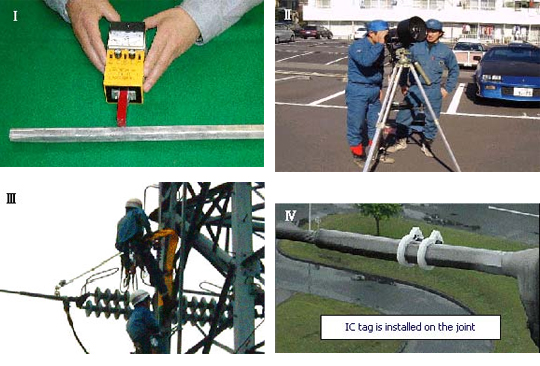

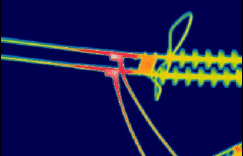

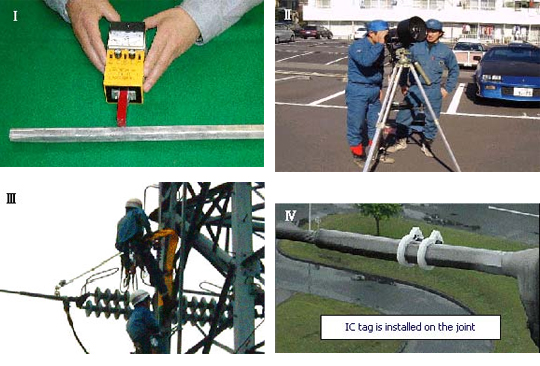

The Check of compression joints

- I. Detector of the position of steel sleeve

- II. Thermal video system

- III. Thermometer for active line

- IV. IC tag for temperature measurement