CO2 reduction measures are vital to the transportation sector, as it relies on fossil energies for most of its energy needs. TEPCO promotes electrification based on the use of low-CO2 electricity and contributes to reducing carbon emissions in the transportation sector by disseminating electric vehicles (EV) and an idle reduction external power supply system that would reduce engine idling.

We are actively encouraging the introduction of electric vehicles provide excellent environmental performance, and are also helping to develop the necessary infrastructure for electric vehicles dissemination by pursuing the development of quick chargers and standardization of charging methods.

Electric vehicles do not burn fuel to run, and therefore do not emit exhaust gas. They contribute to mitigating air pollution and can reduce CO2 emissions by approximately 70% compared to gasoline vehicles of the same class. CO2 emissions from passenger vehicles account for roughly 10% of total emission in Japan, and came to 119 million tons in FY2008, but electric vehicles would contribute to lowering this emission volume.

CO2 reduction effect of electric vehicles

(when a light vehicle travels 10,000 km)

K-car gasoline mileage 19.2 km/l (Japan Mini Vehicles Association, "Shireba shiruhodo iine! Keijidosha (2008 edition)" (informational pamphlet on K-car))

EV mileage 10 km/kWh (calculated based on travel distance per charge in 10-15 mode announced by Fuji Heavy Industries Ltd. and Mitsubishi Motors Corporation and total electric power of the drive battery); Charging efficiency 0.90

CO2 emission intensity

We are actively promoting the introduction of electric vehicles, and have introduced 310 electric vehicles to our offices in FY2009. This has brought the number of electric vehicles among our fleet of 8,090 commercial vehicles to 417, as of March 31, 2010. We plan to increase the number of electric vehicles we possess to around 3,000 in the future, to achieve a CO2 emission reduction effect worth approximately 2,500 t/year.

Commercial electric vehicle used by TEPCO

Commercial electric vehicle used by TEPCO

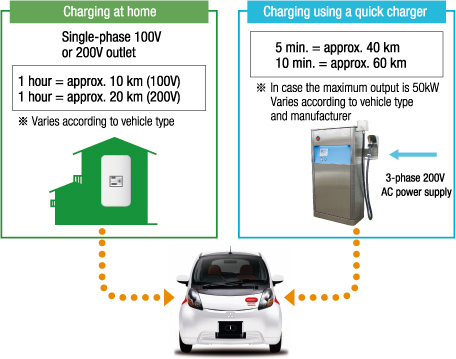

TEPCO is utilizing the charging technologies it has cultivated over many years, to develop quick chargers that are compatible with any electric vehicle regardless of manufacturer, and is conducting demonstration tests with manufacturers and other partners. A 10-minute charge by quick charger can provide sufficient power for an electric vehicle to travel about 60 km.

Household power supply outlets can be used to charge electric vehicles. With an hour of charging, an electric vehicle can travel about 10 km when using a 100V outlet and about 20 km when using a 200V outlet.

electric vehicles charging methods

We actively support measures for enhancing the performance of quick chargers and disseminating their use. In March 2010, we founded the CHAdeMO Association in collaboration with Toyota Motor Corporation, Nissan Motor Co., Ltd., Mitsubishi Motors Corporation, and Fuji Heavy Industries Ltd. In addition to these executive members, the association is also represented by 270 Japanese and foreign companies and organizations, including charging equipment manufacturers, charging service companies, and supporting members consisting of private companies and public agencies (as of August 4, 2010).

CHAdeMO Association promotes the dissemination of electric vehicles by supporting the improvement of charging technologies, standardization of charging methods, and provision of information on rapid chargers abroad.

CHAdeMO Association logo

CHAdeMO Association logo

We have developed an idle reduction external power supply system, and have commercialized the system in 2007, to reduce CO2 levels from transport businesses, in particular. By installing an externally powered airconditioning unit in trucks and drawing electricity from an external power supply stand, truck drivers could use the air conditioner in the truck cab even with the engine turned off, during waiting and resting periods at parking facilities and rest stops. The system is expected to cut fuel costs by approximately 60% and reduce CO2 emissions by as much as 98%, compared to keeping engines idling.

Overview of the external power supply system

CO2 emission reduction potential

Calculation conditions

CO2 emission intensity: diesel fuel 2.58 kg-CO2/l (Ministry of the Environment, “Greenhouse Gas Emissions Calculation and Reporting Manual”); electricity 0.324 kg-CO2/kWh (FY2009 TEPCO performance)

Fuel consumption by large trucks: 1.56l/h (calculated using survey data from the Ministry of the Environment)

Electricity consumption by large trucks: 0.22 kWh/h (TEPCO survey value)

Power supply stands are widely used at truck stations and Highway service areas, truck waiting zones in wholesale markets and airports, and various other locations. In FY2009, we introduced the system to the Dangozaka service area and to Narita International Airport, located within our service area, as well as promoted the dissemination of the system in areas outside our service area. As a result, there are now power supply stands for 203 vehicles (111 units) in operation in 29 locations throughout Japan, as of March 31, 2010.

Installation of power supply stands (as of March 31, 2010)

At Tsukiji Market, Tokyo Metropolitan Central Wholesale Market, we implemented a demonstration test on the environmental load reduction potential of the external power supply system, from May 2009 to March 2010. The test was designated a model project of the Ministry of Economy, Trade and Industry, and was performed using frozen tuna trucks, which normally keep their engine running during the whole time they await their load in Tsukiji Market. The refrigeration unit in the body of the trucks and the air-conditioning unit in the driver's cabin were powered by electricity with the engine turned off, to examine the effects of using electricity in reducing CO2, NOx (nitrogen oxides), SPM (suspended particulate matter), noise, and vibration levels.

The test verified environmental load reductions in all test items, as well as confirmed the validity of new technologies, such as wall-mounted power supply stands that can be installed even in narrow or tight spaces.

Power supply system introduced to Tsukiji Market

Power supply system introduced to Tsukiji Market

© Tokyo Electric Power Company Holdings, Inc.